Precision Dosing for Special Applications

The use of micro-fluidic processes is not limited to research labs. Industrial companies are already successfully using CETONI Flow-systems for the precision dosing of fluids. The bandwidth of application is enormous and ranges from model solutions to large-scale and automated systems.

Varnishes, Lubricants and Adhesives

The application of finishes requires a jerk-free media supply system. Our high-precision syringe pumps are capable of dosing without pulsation and at high precision down into the nano-liter range, therefore providing a homogenous coating process. A media supply that is interruption-free and independent from the syringe volume is made possible by combining our special valves with our innovative QmixElements control and automation software, which smoothly blends the operation of alternating syringe pumps during continuous media transport.

Thanks to its modular design and the available interfaces, the dosing system can be easily expanded and integrated into existing coating systems. In addition, its operation is simple and allows for efficient processes, thanks to the ability to exchange syringes very fast instead of employing complex rinsing and cleaning procedures.

Flow Chemistry

Flow chemistry is becoming increasingly interesting with regard to the implementation of industrial processes. Requiring only small quantities of poisonous or highly sensitive substances makes an important contribution toward achieving improved process safety and control. This simplifies the control of endothermic and exothermic processes as well as elevating temperatures beyond the boiling point with regard to critical reactions. The miniaturization of processes increases efficiency, while lowering costs at the same time. Even scaling up a proven reaction becomes quick and easy.

Particle Synthesis

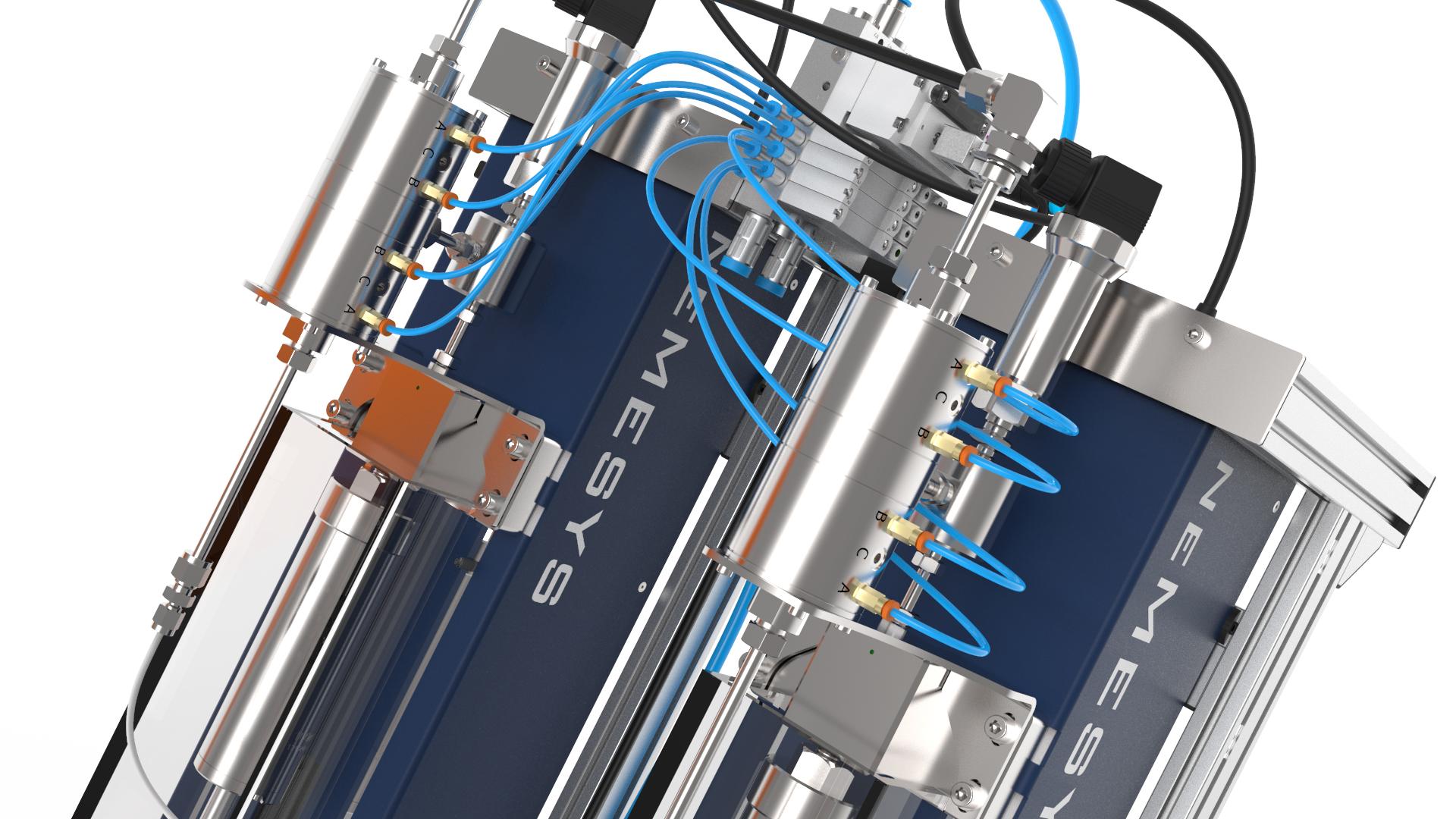

Particle synthesis requires a setup providing extremely precise fluid dosing at very continuous flowrates. A media supply that is uninterruptable and independent from the syringe volume (continuous flow) is made possible by our innovative QmixElements control and automation software. By using an intelligent algorithm, it ensures the smooth blending of alternating syringe pumps during continuous media transport, to a point where it becomes practically unnoticeable. Thanks to the ability to choose from various different material combinations with regard to the medium-affected components, the fluid system is resistant to many different chemicals. Also, it makes no difference whether the system is operated under normal atmospheric conditions or high pressure. The neMESYS technology fulfills both requirements with excellent results.

Complex Systems and Integration

Apart from compact setups, our modules can also be used to realize highly complex systems, that feature pressure and temperature control or could be fitted with sample handling components, such as our rotAXYS system or additional analysis modules. In addition, they can be automated using our comprehensive QmixElements controlling software.