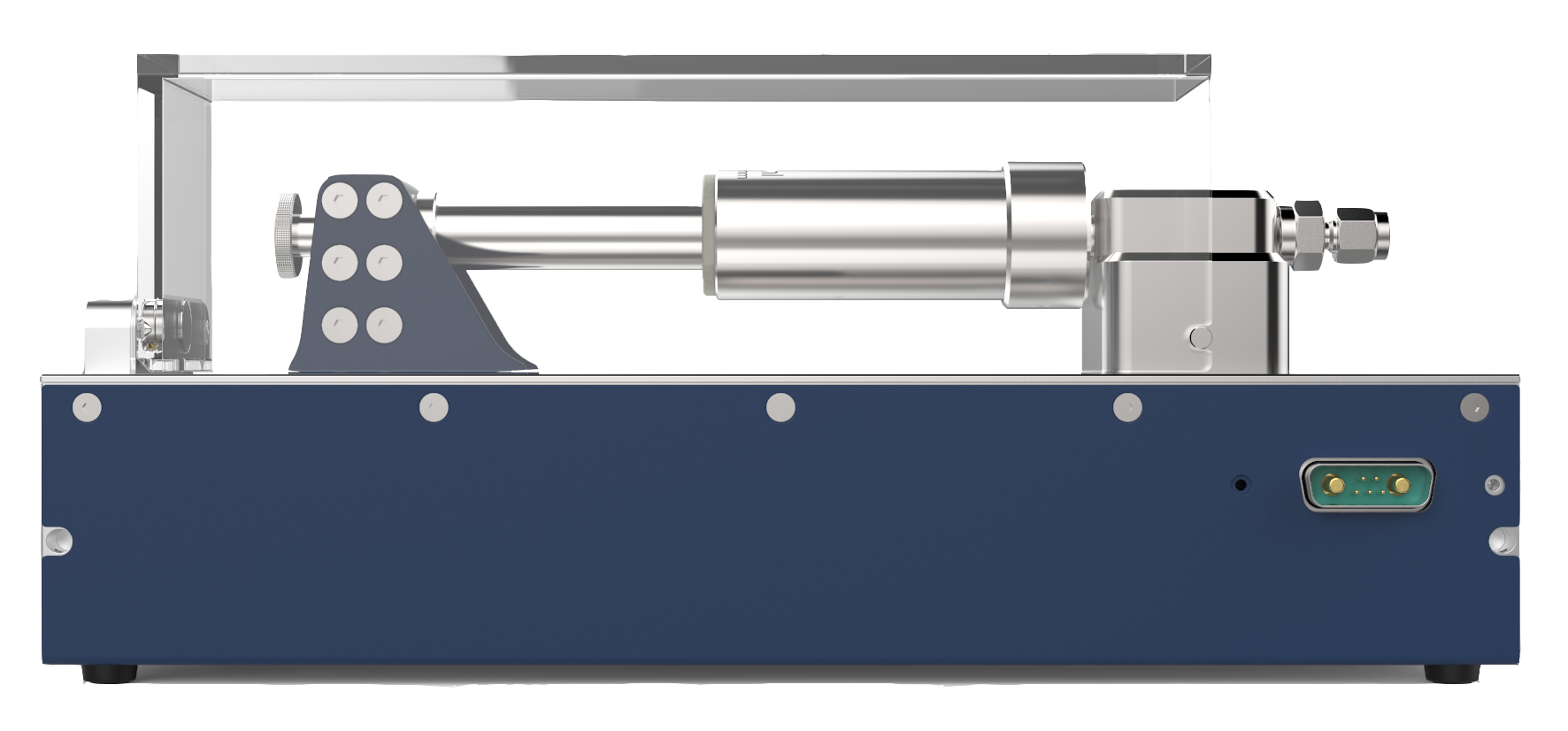

Extremely versatile

Are you working on a chromatography application or a test bench, or is your medium itself highly viscous or otherwise demanding? Then our Nemesys high-pressure module syringe pump offers you enormous performance in an exceptionally compact design.

With the force of 2600 Newton, distributed over various steel syringes from 3 ml to 100 ml capacity, you can either achieve syringe pressures of up to 500 bar or a high volume flow of up to 825 ml/min at moderate pressures.

This range makes the high-pressure syringe pump interesting not only for handling liquid, gaseous or even supercritical fluids, but also for high-throughput applications and syntheses. The integrated pressure sensor and an additional transparent protective cover provide additional safety.

Let it Flow

Many fluidic processes that were conventionally carried out in batch processes can be converted into progressive flow processes, which offer a number of advantages over conservative approaches, such as high process reliability, homogeneous reaction conditions, as well as time and resource savings. The areas of application extend from biology to chemistry to physics in different application scenarios, which are clearly described under Application Notes.

We will show you how you can convert your batch process into an advanced flow process or how to automate laboratory processes that were previously manual with the help of Cobomation. Just talk to us!

Software & Accessories

Simple operation, flexible automation and barrier-free integration

In addition to the intuitive control of your syringe pumps, our CETONI Elements software offers you all options for the easy automation of flow processes, in order to generate meaningful results quickly and reliably.

For seamless integration into your familiar software environment (C++, Python, LabView, MATLAB, etc.), we also offer you the extensive CETONI SDK (Software Development Kit) for Windows and Linux applications.

High pressure syringes

Thanks to the variety of precision steel syringes made from different materials, you can either expand the areas of application of your syringe pump in the long term or adapt flexibly to the needs of your application at any time.

High pressure valves & pressure sensors

With a choice of different valve variants made of different materials, you either simply automate the filling of your syringe pump or generate an uninterrupted (continuous) flow of fluid to your device. Pressure sensors in the process protect your devices, even enable pressure control using a syringe pump and collect important and evaluable process data.

Industries and Applications

Microfluidics in Chemistry

Microfluidics in Chemistry

Precision Dosing in Industry

Precision Dosing in Industry

Precision Dosing in Industry

Microfluidic Processes in Geology, Petrology, Mineralogy

Microfluidic Processes in Geology, Petrology, Mineralogy