In unserer Rubrik #CETONIacademy diskutieren wir künftig in regelmäßigen Abständen Grundlagen der Mikrofluidik. Den Anfang machen wir mit dem Begriff „pulsationsfrei“, denn nichts ist in der Mikrofluidik essentieller als ein gleichmäßiger Fluidstrom.

Was versteht man unter pulsationsfrei?

Die Mikrofluidik zeichnet sich durch Anwendungen mit kleinsten Strömen in kleinsten Kavitäten aus. Zahlreiche Anwendungen so zum Beispiel in der Flow Chemie setzen gleichmäßige – pulsationsfreie – Flüssigkeitsströme voraus, um kontinuierlich gleiche Mischverhältnisse zu gewährleisten, und dies auch in kleinsten Zeitskalen. Auch beim Erzeugen und Manipulieren kompartimentierter Ströme in der Bio-Chemie ist ein gleichmäßiger Fluidstrom notwendig.

Pulsationen bezeichnen in der Mikrofluidik Schwingungen der tatsächlichen Flussrate, wobei die gemittelte Flussrate durchaus korrekt sein kann. Bei extrem kleinen Flussraten, wie sie in der Mikrofluidik naturgemäß vorkommen, können Pulsationen, relativ betrachtet, groß sein und sich entsprechend negativ auf kleinskalige Prozesse auswirken. Wenngleich eine absolute Pulsationsfreiheit in der Mechanik technisch nicht möglich ist, so können die Pulsationen dennoch so weit reduziert werden, dass diese mit den existierenden Messmitteln und -methoden nicht mehr messbar sind oder keinen Einfluss auf den Anwendungsprozess haben. Dann sprechen wir von „pulsationsfrei“.

pictures Friedrich-Schiller-University Jena

Mit dem Auto blind um die Kurve fahren

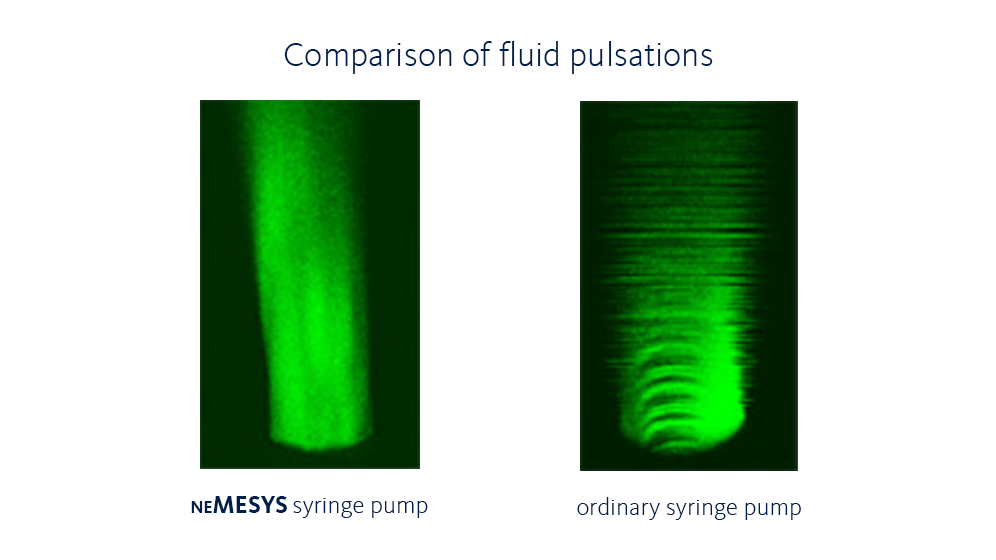

Spritzenpumpen ermöglichen volumetrisches Fördern mittels Verdrängung des Volumens durch einen Kolben definierten Querschnittes, der mit einer definierten Geschwindigkeit verfahren wird. Um mit einer Spritzenpumpe eine konstante Flussrate zu erzeugen, ist ein extrem gleichmäßiger Lauf der lateralen Verfahrbewegung des Spritzenkolbens notwendig. Hier stoßen handelsübliche Spritzenpumpen oft an ihr Limit, denn ihr Antrieb ist häufig stark auflösungsbegrenzt, was wiederum Pulsationen zur Folge hat. Doch gerade die Auflösung der Messelemente der Pumpe (Encoder) ist entscheidend.

Die laterale Verfahrbewegung des Kolbens muss durch ein im Regelkreis betriebenes Antriebssystem erzeugt werden. Üblicherweise wird hierfür die Drehbewegung eines Elektromotors über einen Spindeltrieb in eine Linearbewegung umgesetzt. Ein Positionsregler kontrolliert dabei in regelmäßigen – möglichst kleinen – Abständen die Ist-Position, respektive den Drehwinkel, des Motors und vergleicht sie mit der Soll-Position zum jeweiligen Zeitpunkt. Aus der ermittelten Soll-Ist-Abweichung ergibt sich, inwieweit die Stellgröße des Motors mittels Motorstromanpassung nachgeregelt werden muss. Eine geringe Auflösung des Positionssensors führt insbesondere bei langsamen Bewegungen zu großen Abstandsintervallen der Messung. Der Controller erhält folglich nur in relativ großen Zeitabständen Informationen zur tatsächlichen Position des Kolbens, was wiederum das Nachregeln erschwert und in der Folge zu Geschwindigkeitsschwankungen führt.

Die Systematik wird am folgenden Beispiel deutlicher: Stellen wir uns einen Regelkreis vor, bei dem ein Autofahrer eine gewisse Strecke hinter sich legen muss, seine Augen zum Korrigieren seiner Position allerdings nur alle 2 Sekunden kurz öffnen darf. Mag das Experiment auf gerader Strecke mit einer Geschwindigkeit von 20 km/h noch funktionieren, wird das Fahren einer Kurve (Störgröße) kaum möglich sein. Der Fahrweg dürfte weniger einer Kurve als einem Polygon entsprechen, da der Fahrer beim Öffnen seiner Augen die Soll-Ist-Abweichungen seiner Position durch entsprechend starken Lenkeinschlag zu korrigieren versucht, um nicht von der Straße abzukommen.

Höchste Auflösung – höchste Qualität

Niedrige Abtastraten führen beim Spritzenantrieb zu ständigem Nachregeln durch Erhöhen oder Senken des Motorstroms. Ein sauberer Rundlauf kommt nicht zu Stande. Es entstehen Pulsationen. Bei CETONI setzen wir deshalb auf qualitativ hochwertigste Komponenten und statten unsere Spritzenpumpen mit Antrieben aus, deren Auflösung im Submikrometerbereich liegt. Die Pulsation unserer Antriebe ist folglich so gering, dass sie für die im Moment etablierten mikrofluidischen Verfahren keine Rolle spielt. Die neMESYS Spritzenpumpen eignen sich somit für mikrofluidische Applikationen, die extremste Genauigkeit erfordern.

Unser Innovationsgeist und die fortschreitende Miniaturisierung der Chemie treibt uns an, uns nicht auf dem Erreichten auszuruhen, sondern unsere Mikrofluidik-Systeme ständig weiter zu entwickeln und zu verbessern. Nur so werden wir unserer Vision gerecht und können Spitzenforschung und Entwicklung auf höchstem Niveau ermöglichen.