Typical areas of application for microfluidics

Microfluidics refers to the manipulation of small quantities of fluids, often in the range of micro- and nanoliters, in tiny channels and structures. This technology is used in various fields of application.

- Analytics and diagnostics:

Microfluidics is often used in lab-on-a-chip systems to analyze samples in small volumes.

Rapid diagnosis of diseases, detection of biomarkers and genetic analysis are typical applications.

- Medical applications:

The development of miniaturized drug delivery systems, including implantable micropumps.

Lab-on-a-chip technologies for point-of-care diagnostics and disease monitoring.

- Chemical synthesis and reactions:

Carrying out chemical reactions in small volumes, which leads to faster reaction times and more precise results.

Optimization of synthesis processes and production of nanomaterials.

- Environmental monitoring:

Miniaturized sensors for monitoring environmental parameters such as water quality, air pollution and soil analysis.

In-situ analysis of environmental samples.

- Food and beverage industry:

Control of processes in food production, such as mixing, dosing and filling.

Rapid analysis of food samples for quality control.

- Biotechnology:

Cell manipulation, cell sorting and analysis of individual cells.

Research into protein folding and gene expression at the level of individual molecules.

- Pharmaceuticals:

Development of miniaturized devices for high-throughput drug screening.

Improvement of drug delivery systems.

- Optofluidics:

Integration of optical components with microfluidic systems for applications in optical signal processing and sensor technology.

- Energy:

Microfluidic systems are used in fuel cells and batteries to improve efficiency.

Cooling of electronic devices through microchannels for better heat dissipation.

- Research and development:

Microfluidics is used in laboratories for researching new technologies and developing prototypes.

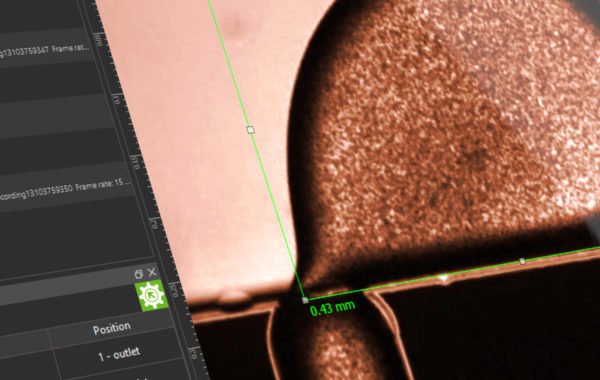

The precision of the dosing system

plays a decisive role in various application areas of microfluidics and significantly influences the success of the respective applications. In lab-on-a-chip systems or diagnostic platforms, precise dosing is crucial to avoid falsified analysis results and ensure diagnostic accuracy. With microfluidic drug delivery systems, precise dosing is essential to ensure that patients receive the correct amount of drug and to minimize potential health risks. In biotechnological applications such as cell culture or the production of biomaterials, precise dosing of nutrients and other substances ensures the success of the processes. For chemical synthesis processes in microfluidic channels, the precise dosing of reagents is crucial in order to control the reaction conditions and obtain the desired products. In food production, the precise dosing of ingredients plays a key role in ensuring the quality and consistency of products. For research and development work in laboratories where microfluidics are used, the precision of the dosing system is crucial for the reproducibility of experiments and the validity of the data obtained. In the development of microfluidic biosensors, precise dosing of samples and reagents is necessary to achieve sensitive and reliable sensor results. In applications such as fuel cells or batteries, precise dosing of electrolyte solutions or fuels is crucial for the efficiency and performance of the system.

The precision of the dosing system is therefore not only of great importance for the accuracy of experiments, but also for safety and efficacy in medical and biotechnological contexts, for example.