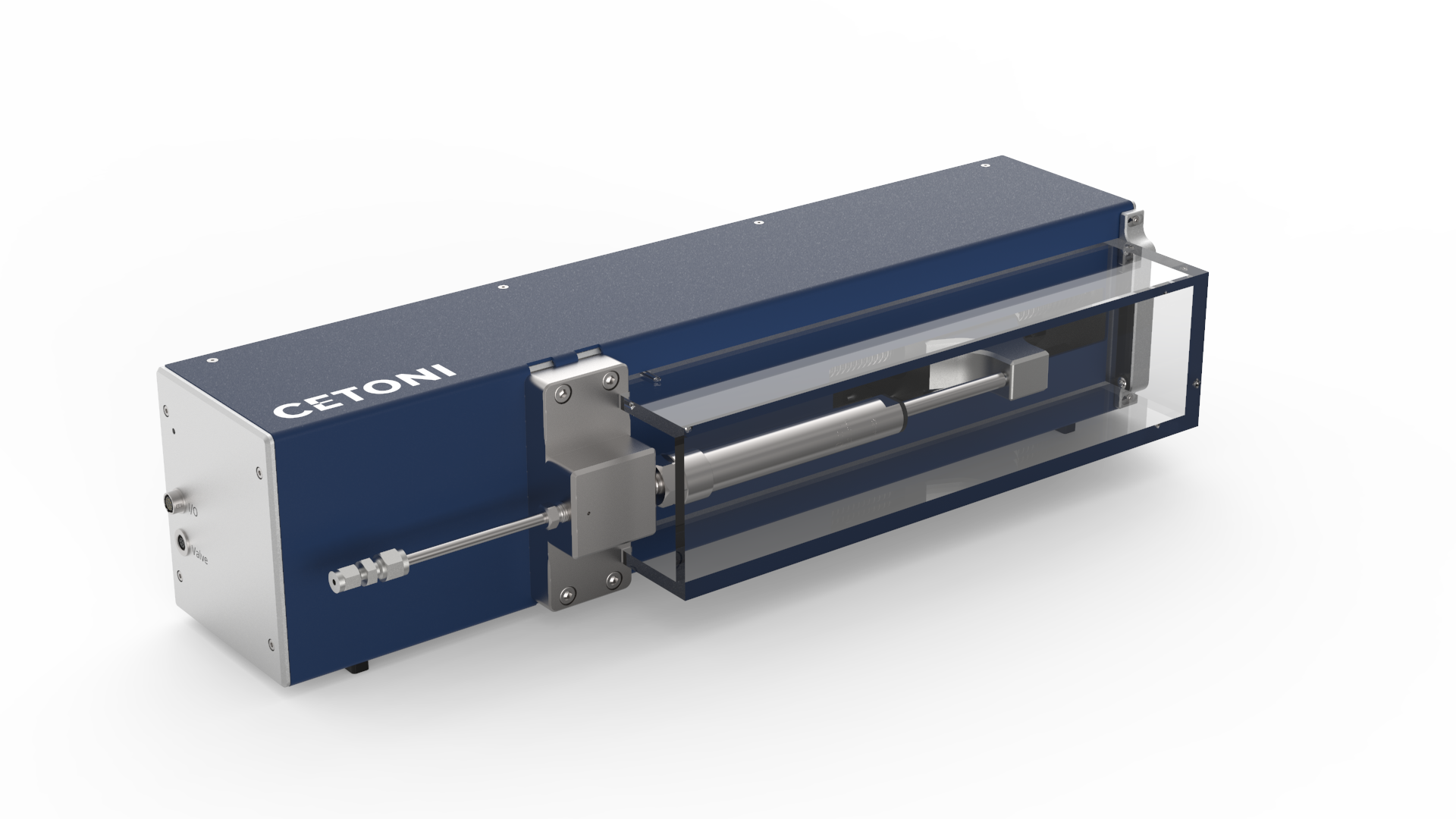

Pulsation-free | 12 nl/min – 1500 ml/min | 0 – 1000 bar | Continuous flow | Modular | Software control | Compact

High throughput and high pressure applications up to 1000 bar

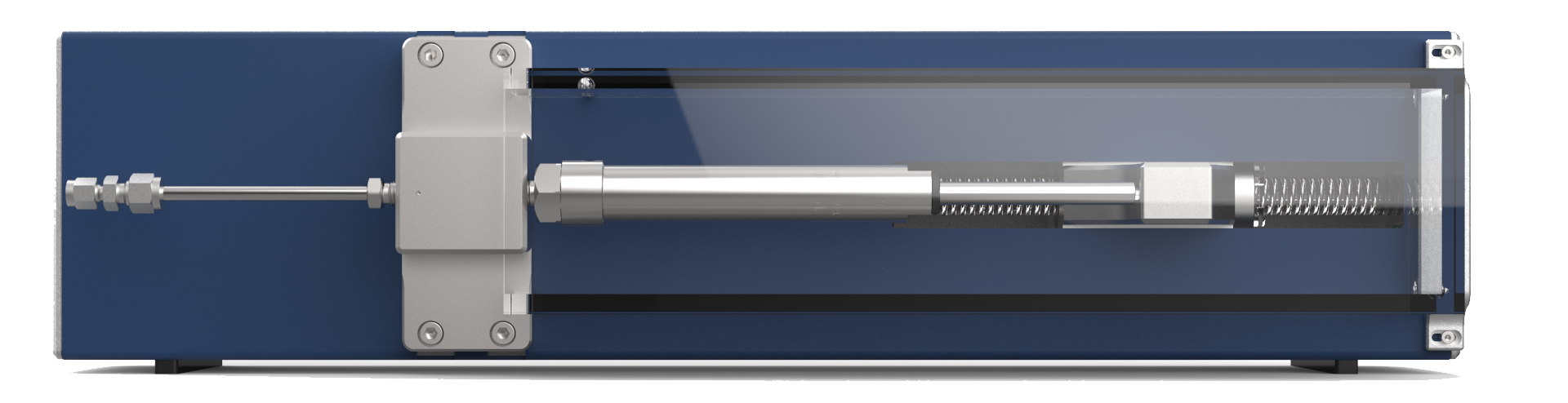

Under our earth’s crust, which is millions of years old, not only has time left its mark, there is also enormous pressure. It is therefore logical that to research the raw materials oil and natural gas stored under this crust, equally high pressures must be generated. If the highest accuracy requirements are also placed on it, essential for meaningful measured values, the Nemesys ultra-high pressure module can make full use of its up to 8000 Newton (approx. 8oo kg weight force) thrust. With the help of the 2 available expansion stages, either up to 890 or up to 1000 bar pressure can be provided for your application.

In addition to applications that require these pressures (e.g. test beds, pressure cells, etc.), this thrust is also ideally suited for metering viscous fluids (paints, lubricants, silicones etc.) in industrial processes. The equally high travel speed also makes the Nemesys ultra-high pressure module interesting for production-scale chemical synthesis, as it can deliver flow rates of up to 1.5 liters per minute using the 250 ml syringe, with proven precision and freedom from pulsation for which Nemesys syringe pumps are known. This means that flow synthesis systems with production volumes in the tonnes-per-year range can be implemented in the smallest of spaces and with all the advantages of flow chemistry.

Compact, versatile and expandable

Thanks to the very compact design and a selection of interchangeable steel syringes, our Nemesys ultra-high pressure module can also be perfectly integrated into test beds or test systems as a flexible and easy-to-use instrument. Features, such as an integrated safety coupling, but also additional valves and pressure measurement technology (up to 1300 bar) make this syringe pump module a robust and safe instrument for your research in extreme areas, as well as in industrial environments.

Let it Flow

Many fluidic processes that were conventionally carried out in batch processes, can be converted into progressive flow processes, and offer a number of advantages over conservative approaches, such as high process reliability, homogeneous reaction conditions, as well as time and resource savings. The areas of application extend from biology to chemistry to physics in different application scenarios, which we have clearly described for you under Application Notes.

We will show you how you can convert your batch process into an advanced flow process or how to automate laboratory processes that were previously manual with the help of Cobomation. Just talk to us!

Software & Accessories

Simple operation, flexible automation and barrier-free integration

In addition to the intuitive control of your syringe pumps, our CETONI Elements software offers you all options for the easy automation of flow processes, in order to generate meaningful results quickly and reliably.

For seamless integration into your familiar software environment (C ++, Python, LabView, Matlab, etc.), we also offer you the extensive CETONI SDK (Software Development Kit) for Windows and Linux applications.

Valves and bracket for integration

With the right accessories, such as our vertical bracket for stable positioning of the syringe pump system in your application, or special high-pressure valves up to 1300 bar operating pressure, we will work with you to configure your individual system, which is ideal for your application. Whether geology, petrochemicals, industrial fine dosing or industrial coating, or in applications requiring high pressures with high precision or compactness, our Nemesys ultra-high pressure syringe pump is the right solution for you!

Industries and Applications

Microfluidic solutions in biology

Microfluidic solutions in biology

Microfluidic Processes in Geology, Petrology, Mineralogy

Microfluidic Processes in Geology, Petrology, Mineralogy

Microfluidic Processes in Geology, Petrology, Mineralogy

Precision Dosing in Industry

Precision Dosing in Industry