We offer you various options for integrating our devices. Where other manufacturers offer RS232 interfaces with their own serial protocols for connection, we provide you with modern interfaces such as USB or CAN, the standardized open communication protocol, CANopen, and extensive, convenient programming libraries.

Using the CAN interface, CANopen capable applications and controllers can access all device parameters. The use of the CAN bus and standardized CANopen device profiles guarantee that the system can be expanded. The Connectivity Guide supports you in your search for information regarding the integration/connection of our devices to your control solution.

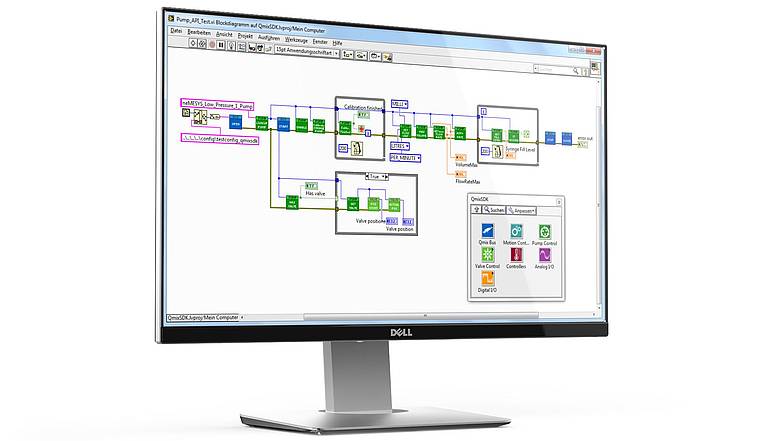

PC

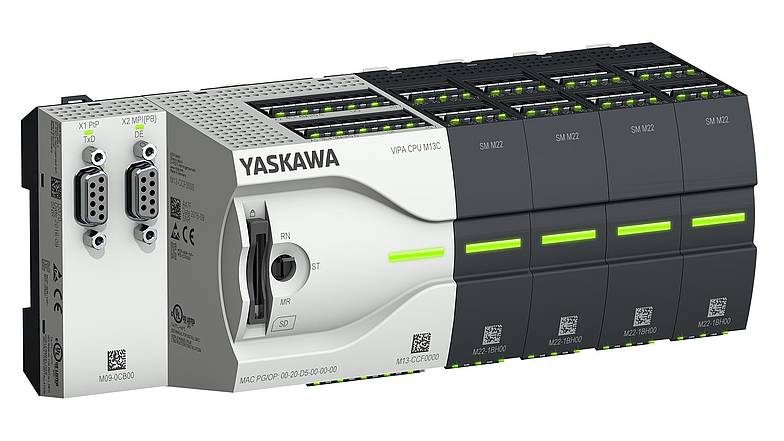

PLC

Connect and control CETONI devices with a PLC

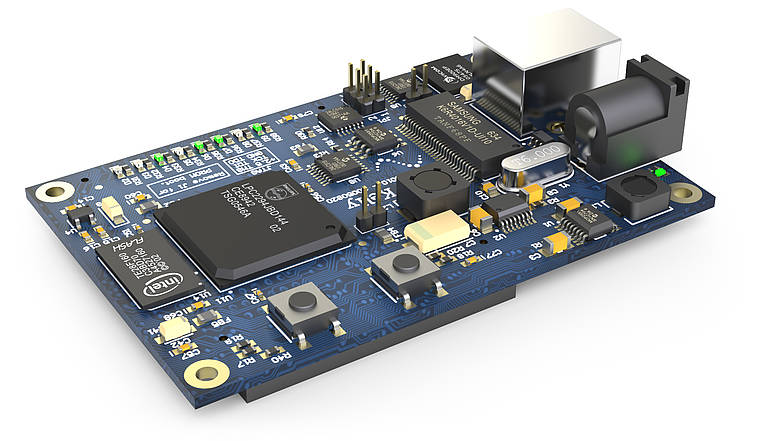

Embedded/microcontroller control

Use your own control solution with RS232 interface

Embedded controller

We use our own control solution to control CETONI devices. Our controller has CAN or RS232 interfaces.

Feature Matrix

The following matrix gives you a quick overview of which features of our devices are available to you with the various integration options:

| CETONI Elements | CETONI SDK/Python/LabVIEW | RS232 C-Library | CAN/RS232 Interface | ||

| Volume Dosing | ✔ | ✔ | ✔ | manual | |

| Constant Flow Generation | ✔ | ✔ | ✔ | manual | |

| Continuous Flow (Cross Flow) | ✔ | ✔ | — | — | |

| Continuous Flow (Pressure-Controlled Switching) | ✔ | planned | — | — | |

| Pressure-Controlled Flow | ✔ | ✔ | — | — | |

| Initialization (Homing—except Nemesys S/M) | ✔ | ✔ | ✔ | manual | |

| Valve Switching | ✔ | ✔ | ✔ | manual | |

| Automatic Valve Control | ✔ | — | — | — | |

| External Pressure Sensor on Nemesys I/O | ✔ | ✔ | manual | manual | |

| Valves / Pressure Sensors on CETONI I/O Module | ✔ | manual | manual (not documented) | manual (not documented) | |

| Syringe Configuration | ✔ | ✔ | — | — | |

| SI Units | ✔ | ✔ | — | — | |

| Nemesys I/O Read/Write | ✔ | ✔ | manual | manual | |

| Execute Script Programs | ✔ | — | — | — | |

| Lowest Flow Rates | ✔ | ✔ | manual (not documented) | manual (not documented) | |

| Support for: | |||||

| Nemesys Pumps | ✔ | ✔ | ✔ | ✔ | |

| Temperature Control Modules | ✔ | ✔ | — | — | |

| Valve Modules | ✔ | ✔ | manual (not documented) | manual (not documented) | |

| I/O Module | ✔ | ✔ | manual (not documented) | manual (not documented) | |

| Spectrometer | ✔ | — | — | — | |

| Camera | ✔ | — | — | — | |

| Positioning Systems | ✔ | ✔ | — | manual (not documented) | |

| Available for: | CETONI Elements | CETONI SDK/Python | LabVIEW | RS232 C-Library | CAN/RS232 interface |

| Windows | ✔ | ✔ | ✔ | ✔ | ✔ |

| Linux x86 (PC) | — | ✔ | — | ✔ | ✔ |

| Linux ARM (Raspberry PI) | — | ✔ | — | ✔ | ✔ |

| Microcontroller | — | — | — | ✔ | ✔ |

| PLC | — | — | — | — | ✔ |

Legend

manual – the customer can implement this feature himself with reasonable effort. Details on the implementation are described in the Nemesys firmware specification.

manual (not documented) – The implementation of this feature by the customer is theoretically possible with reasonable effort, but not yet documented by CETONI.

planned – There are plans to deliver this feature with a future software version.

on request – Implementation is not planned, but CETONI can carry this out upon request (e.g. as part of an order development).

Any questions?

Application & Sales

- +49 (0) 36602 338-80

- application@cetoni.de