Highest accuracy and gentle dosing

The Nemesys syringe pump impresses with precise liquid delivery down to the sub-nanoliter range. Its innovative drive concept moves the syringe plunger absolutely evenly and thus enables continuously smooth delivery – perfect for precise and sensitive microfluidic applications.

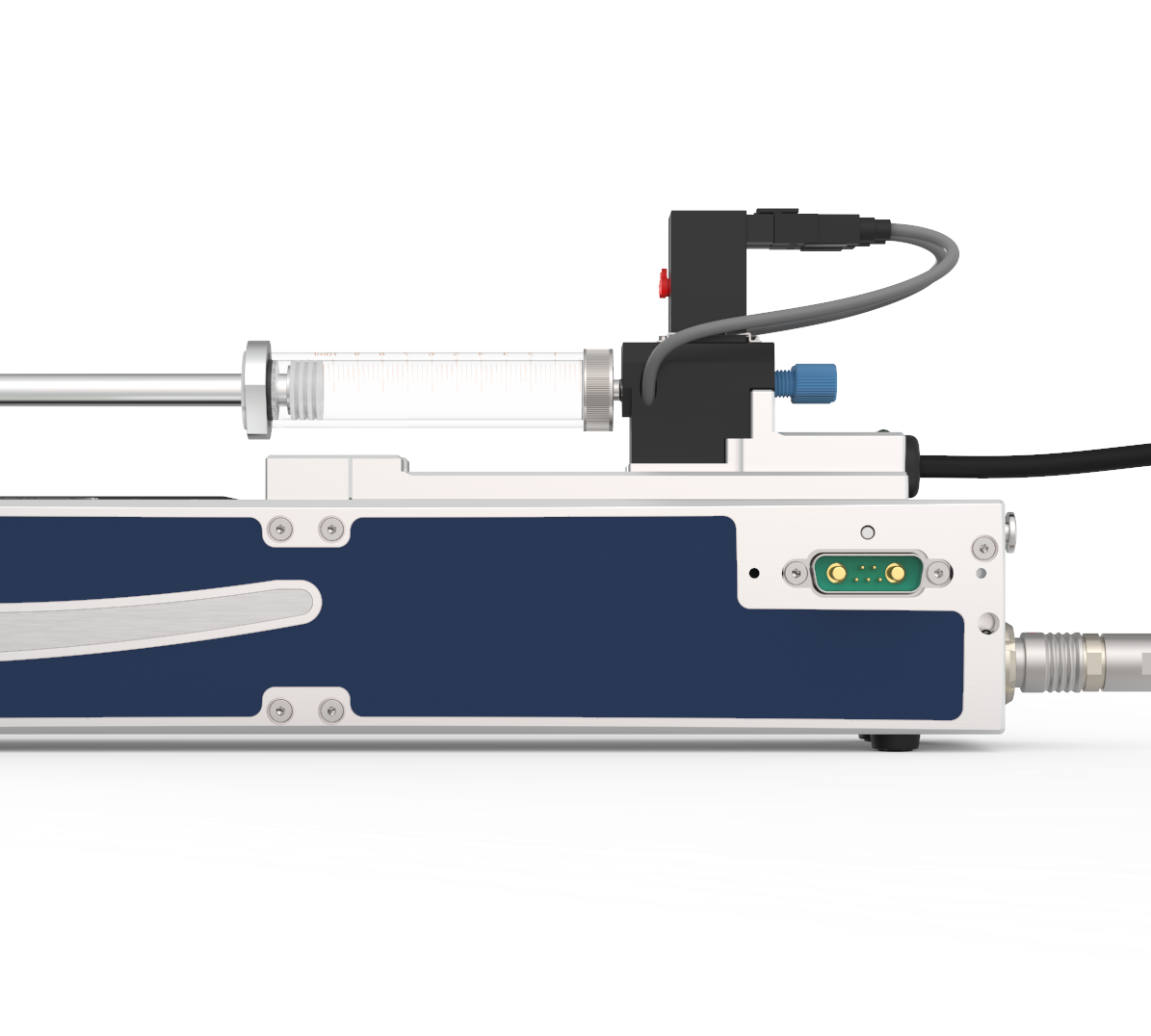

Syringe pump

Nemesys M

Precise performance and reliable strength up to 200 bar

Whether high-pressure injections or highly viscous media – the CETONI Nemesys M offers sufficient reserves for stable and repeatable results. Its sophisticated design also makes it extremely easy to clean, so that it is quickly ready for use again.

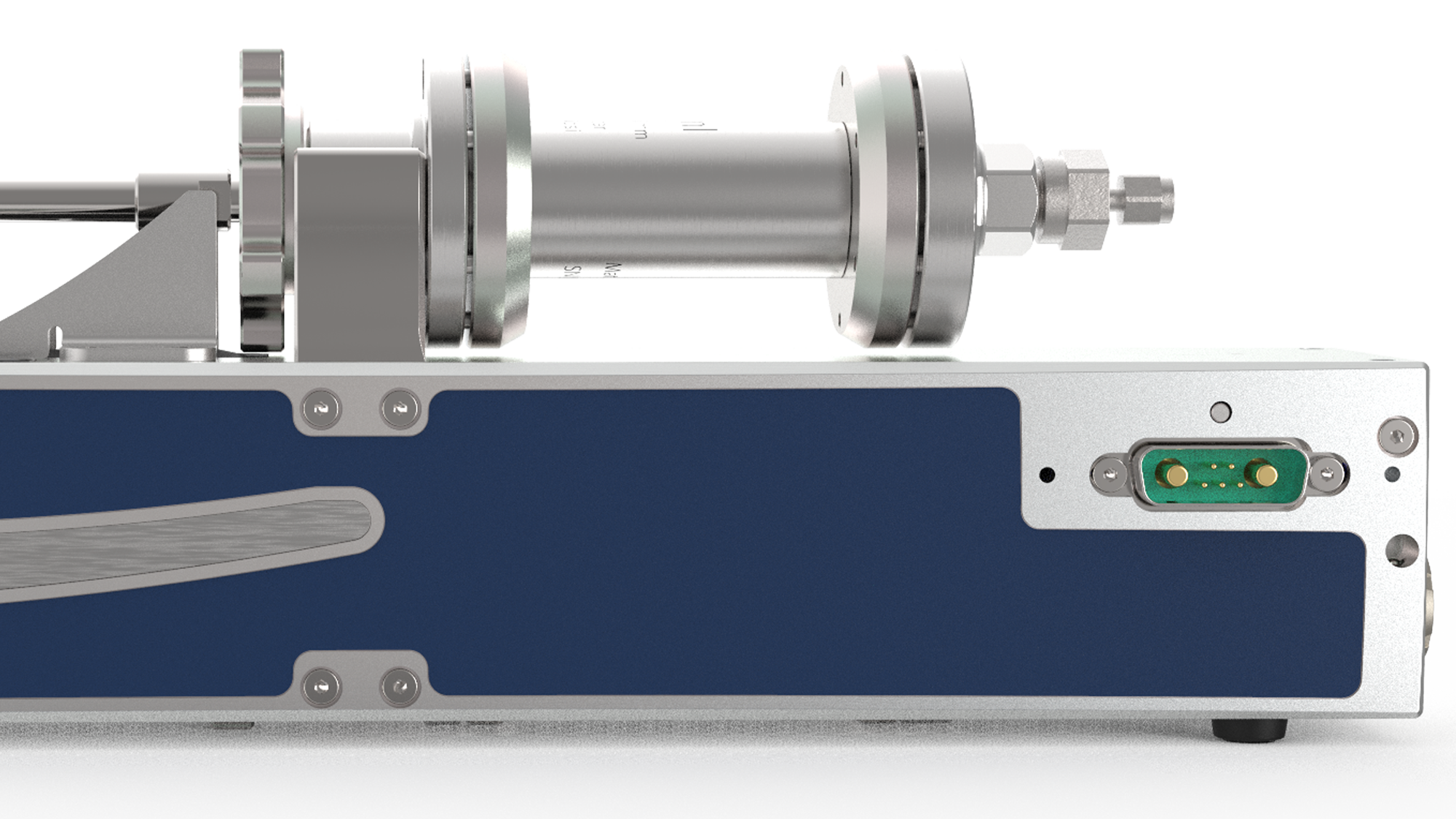

Syringe pump

Nemesys high pressure module

Your solution for test benches and high-pressure applications up to 400 bar

Test benches, high pressure and complex fluids – the Nemesys high-pressure syringe pump delivers. Flexible in use thanks to its compact design and variable syringe sizes.

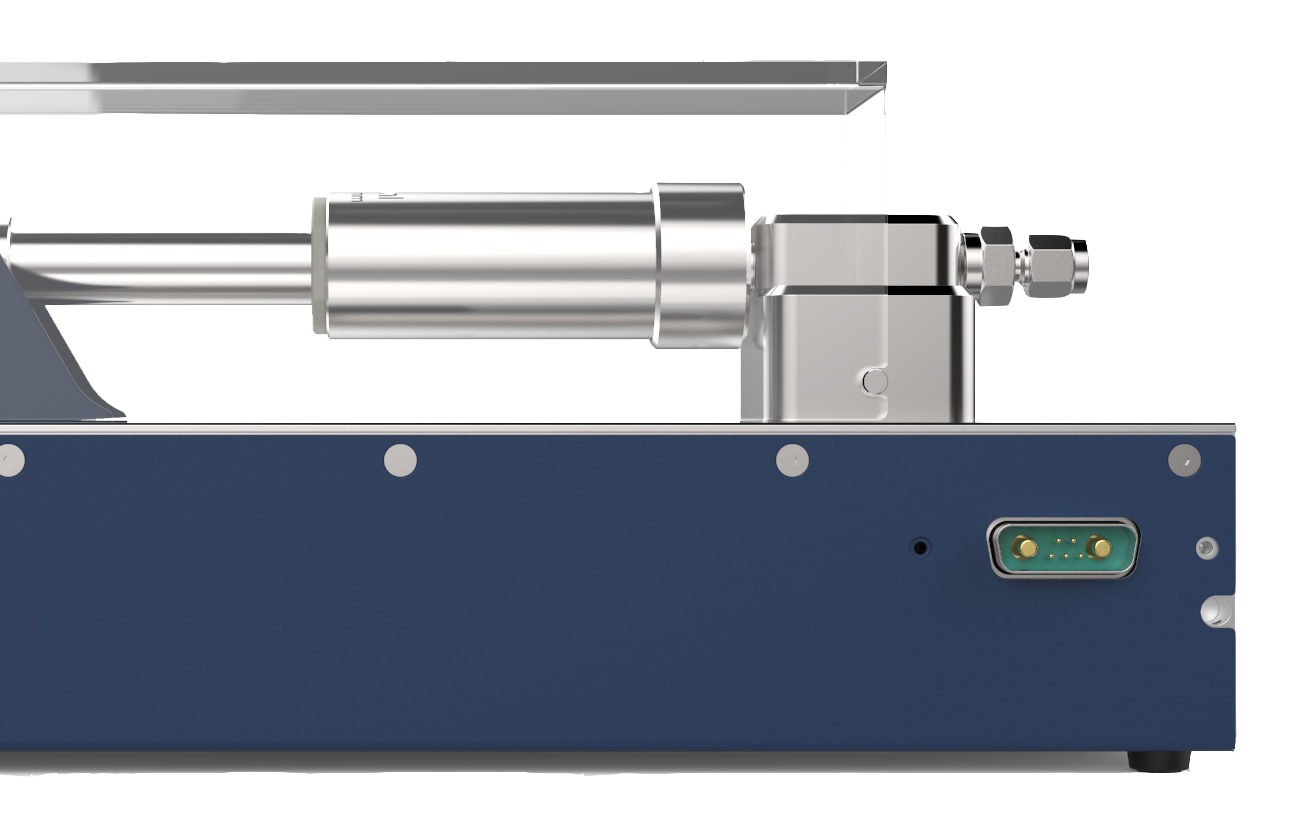

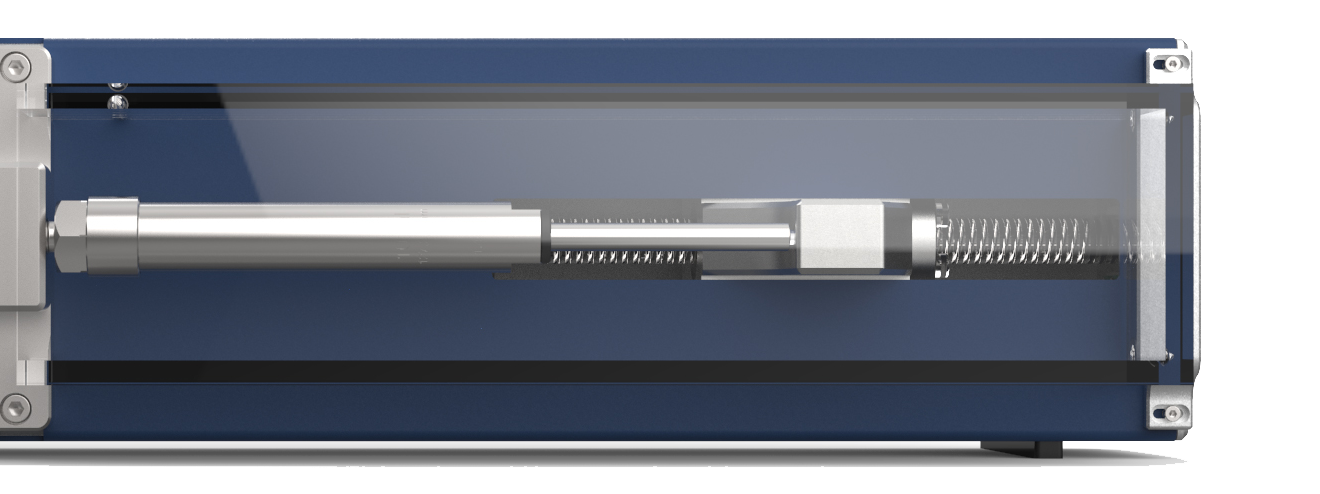

Syringe pump

Nemesys ultra high pressure module

Compact strength for extreme applications up to 1000 bar

Enormous power, absolute stability and outstanding precision make the Nemesys ultra-high pressure pump a reliable partner even under extreme conditions. Its compact design and the choice of different syringes create flexibility for demanding high-pressure and high-throughput applications, continuous media supply and processes with highly viscous materials.

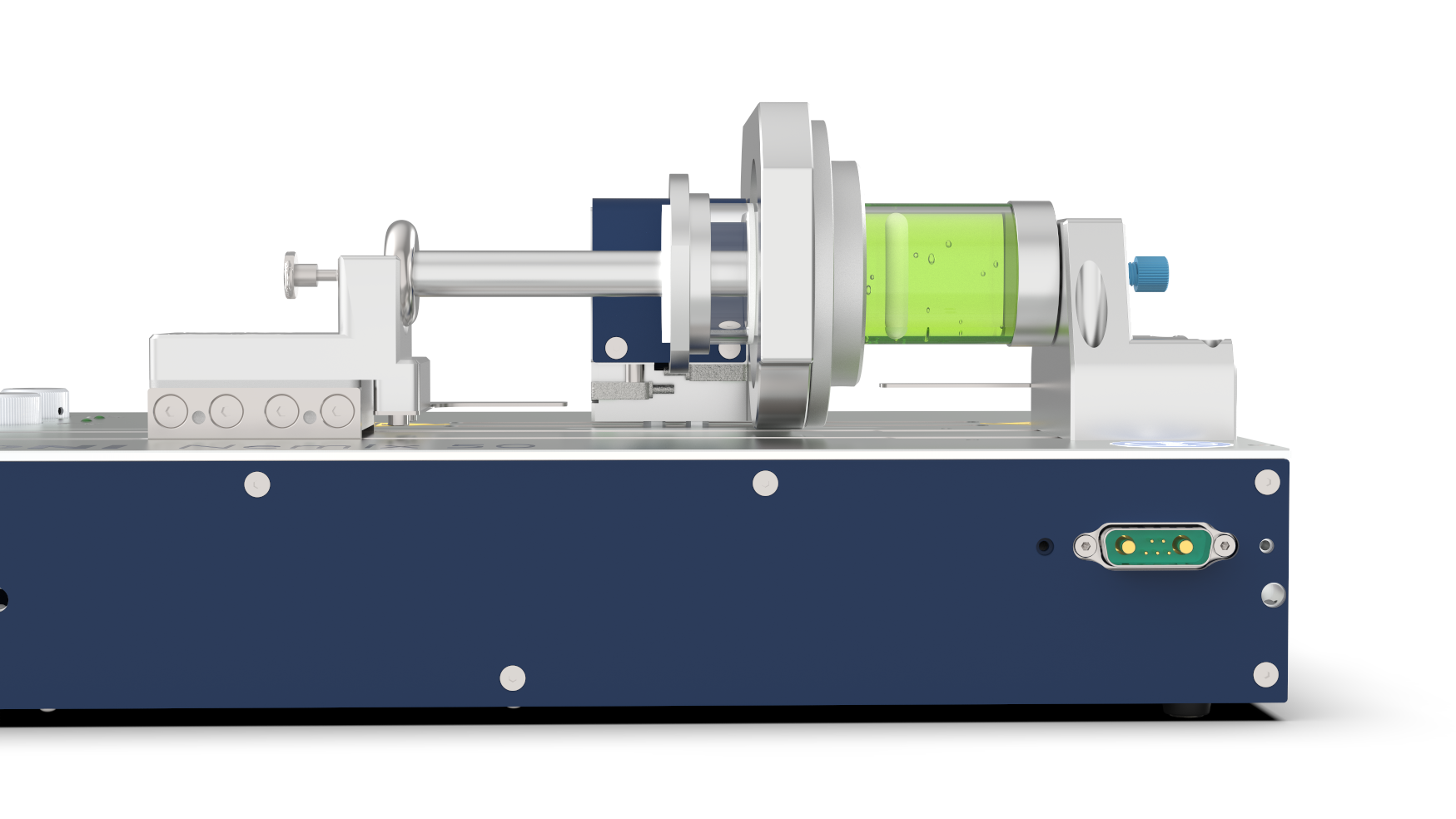

Syringe pump with mixing function

Nemix 50

Perfect mix – without compromise

The Nemix 50 combines the precise Nemesys syringe pump drive with an intelligent stirring device to ensure absolutely homogeneous results. Sedimentation is reliably prevented – for stable processes and maximum efficiency in your applications.

Why pulsation-free?

Microfluidics works with the smallest flows in tiny cavities. For applications such as flow chemistry and biochemistry, uniform, pulsation-free liquid flows are crucial to ensure constant mixing ratios and precise flows.

Pulsations are fluctuations in the flow rate that can be problematic with extremely small flows in microfluidics. Absolute freedom from pulsation is not technically possible, but we can reduce the pulsations to such an extent that they no longer have any measurable effects.

We use high-quality components and precise drives in our syringe pumps to reduce pulsations to a minimum. As a result, our Nemesys syringe pumps provide the extreme accuracy and stable conditions required for microfluidic applications.

Microfluidic applications where pulsation-free dosing is crucial:

Biology: When analyzing and sorting cells, the creation of single-cell analyses requires a constant and pulsation-free flow in order to precisely manipulate and examine the cells.

Chemistry: In flow chemistry, a uniform flow rate is crucial for the reproducibility of reactions and the precise control of mixing ratios, leading to consistent and reliable results.

Industry: In the production of microstructured materials and sensors or homogeneous layers, liquids must be dispensed precisely and evenly to ensure the desired structure and functionality.

What are flow systems?

Many fluidic processes in a wide variety of areas that were conventionally carried out in batch processes, can be converted into progressive flow processes, and offer a number of advantages over conservative approaches, such as high process reliability, homogeneous reaction conditions, time and resource savings. The areas of application range from microbiology to bio-, fine and synthetic chemistry to petrochemistry, geochemistry and geophysics.

For example, if cell cultures were previously cultivated on agar plates, these can now be carried out using microfluidic processes in the smallest droplets, in so-called compartment flows. On one hand, this results in a much greater selectivity of the starting material (few or even just one organism per droplet). On the other hand, an extremely large number of cultures is made possible in the smallest of spaces.

In chemical syntheses and their yield of the desired target substances, it is important to maintain the optimal process parameters, at any time and at any point in the entire reaction volume. This is not possible in large batch approaches.

In the flow process, however, the reaction conditions can be set and controlled very precisely, especially in the case of strongly exothermic reactions or highly reactive substances or mixtures. Often, the optimal parameters are not even known. The search for them is made possible by flow chemistry in connection with inline analysis technology and intelligent software solutions. When researching oil and gas deposits and exploring them, the simulation of the conditions in the deposit and in the rock using flow methods, can bring great advantages in terms of yield and quality of production. In this context, for example in the area of geophysics, geological processes are simulated and examined through the targeted combination of microfluidics and imaging processes (electron accelerator/synchrotron), in order to be able to better predict natural disasters ( read more under Application Notes ).

These few examples alone show that there are hardly any limits to the variety of ideas when using microfluidic techniques. Wherever you reach your limits with conventional methods, it pays to just think in terms of flow!